Advantages of Various Thermal Spray Processes

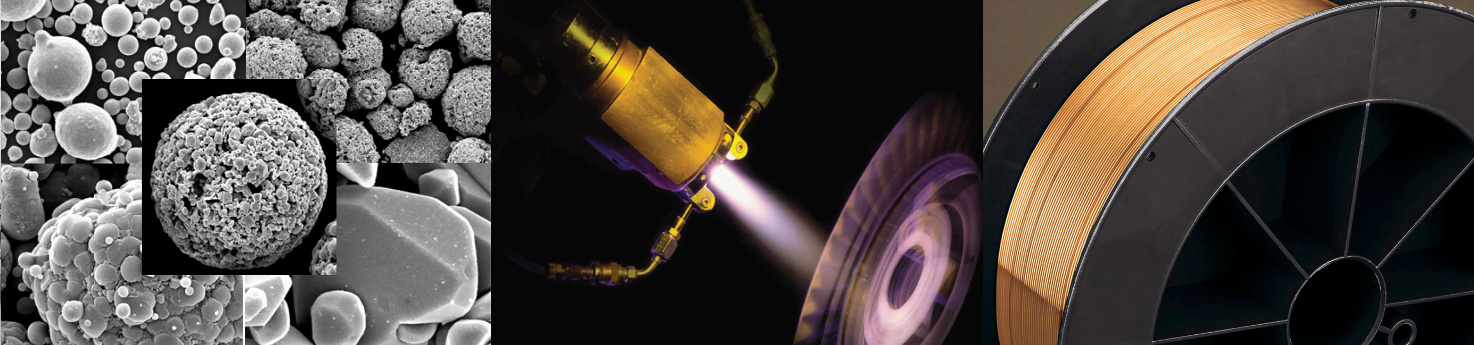

1. Arc Spraying

The main advantages of arc spraying relate to its ease of use and high coating rates:

- Arc spraying has the highest deposition rate of the thermal spraying processes, with rates of 15kg/hr or higher.

- The process offers lower cost coatings when compared with plasma and HVOF spraying. This is because of lower energy cost, high deposition rates and efficiencies and lower material costs associated with a wire consumable.

- Power input is very low at only 5-10 kW compared with greater than 50kW for plasma and HVOF spraying systems.

- Little operator training needed.

- Low heating of the substrate makes arc spraying useful in metallizing thermally sensitive substrates such as capacitors and similar electronic components.

- It is possible to spray two dissimilar wires and produce an intimately mixed coating. Examples include composites of copper and steel on brake discs and clutch pads, and composites of steel and bronze on bearing surfaces and machine tool slideways.

- Higher bond strengths than achievable with flame spraying, even for thicker coatings. Bond strengths are similar over a wide range of spray angles.

- Lower porosity levels than can be achieved by flame spraying.

- Arc spraying does not require use of combustion gases or produce a high-energy plasma, and consequently poses fewer Health & Safety risks than other thermal spray processes.

The main disadvantages associated with arc spraying include:

- The process can be used to spray only electrically conductive materials that are available in a suitable wire form. It is not suitable for spraying cermets or ceramics.

- A large amount of fume and dust is produced, requiring the operator to wear suitable breathing apparatus and protective clothing.

- In general the coating quality does not match that achieved using plasma and HVOF spraying processes.

- Arc sprayed coatings generally contain more porosity and higher amounts of oxide and have lower bond strengths compared with coatings deposited by plasma and HVOF spraying.

2. HVOF Spraying

Advantages of HVOF spraying over other thermal spray processes primarily relate to improved coating quality, such as:

- Higher density (lower porosity) due to greater particle impact velocities.

- Better wear resistance due to harder, tougher coatings.

- Higher hardness due to less degradation of carbide phases.

- Improved corrosion protection due to less through porosity.

- Higher strength bond to the underlying substrate and improved cohesive strength within the coating.

- Lower oxide content due to less in-flight exposure time.

- Retention of powder chemistry due to reduced time at temperature.

- Thicker coating due to less residual stresses.

- Smoother as-sprayed surface due to higher impact velocities and smaller powder sizes.

The disadvantages associated with HVOF spraying include:

- HVOF sprayed coatings can be extremely complex, with their properties and microstructure depending upon numerous processing variables.

- Powder sizes are restricted to a range of about 5 - 60µm, with a need for narrow size distributions.

- HVOF spraying requires experienced, qualified personnel to ensure safe operation and to achieve consistent coating quality.

- As with all the thermal spraying processes, particular health and safety issues should be addressed. HVOF spraying usually needs to be undertaken in a specialised thermal spray booth, with suitable sound attenuation and dust extraction facilities.

- HVOF equipment requires more investment than other thermal spraying processes, for example flame and arc spraying.

- Manual operation of an HVOF spray gun is not recommended and automated manipulation of the gun is usually needed.

- Deposition of coatings is difficult or impossible to achieve on to internal surfaces of small cylindrical components, or other restricted access surfaces, because HVOF spraying needs line of sight to the surface and a spray distance of 150-300 mm.

3. Flame Spraying

Flame spraying is still widely used despite development of more advanced spraying systems. It has distinct advantages over other processes, in particular ease of application and low cost, provided that the coating quality is acceptable.

- The process is simple in design and easy to operate.

- Flame spraying equipment is portable and suitable for manual use without the need for automated manipulators.

- Little operator training is necessary to use the equipment.

- Dust and fume levels are lower than those associated with arc spraying, and noise levels are lower than found with plasma and HVOF spraying. The process can be used without a spray booth, if adequate dust extraction is provided.

- Manual flame spraying can more easily coat components with complex geometry.

- Equipment costs are much lower than for HVOF and plasma spraying. The lower consumable costs (whether powder, wire or rod) and relatively high deposition rates mean that the deposited coating costs are much lower than for most other thermal spraying processes and comparable with those for arc spraying.

The main disadvantage of flame spraying is the level of coating quality.

- Coatings tend to have high porosity (10-20 vol%), low density and high oxide levels (10-20 wt%) for metal deposits, and lower bond strength than coatings prepared by other thermal spraying processes.

- Flame spraying requires line of sight to the surface being coated, similar to all other thermal spraying processes. It is difficult, or impossible, to coat inner surfaces of small diameter bores and other restricted access surfaces.

- As with all thermal spraying processes there are particular health and safety issues that need to be addressed. For flame spraying these relate to protecting the operator from powder, dust and fume. Also the use of flammable gases, including acetylene, requires that safe use and storage of gases be considered.

4. Plasma Spraying

The main advantages of plasma spraying over other thermal spray processes include:

- A wide range of coating materials to meet many different needs, with virtually all materials available in a suitable powder form.

- Higher quality coatings than other more conventional thermal processes such as flame or electrical arc spraying.

- Many types of substrate material, including metals, ceramics, plastics, glass, and composite materials can be coated using plasma spraying.

- The high temperature of a plasma jet makes it particularly suitable for spraying coatings of refractory metals and ceramics, including ZrO2, B4C and tungsten.

- A broader powder particle size range can be used, typically 5-100µm, compared with HVOF spraying.

- Plasma spraying is a well-established coating process that is widely available and well understood.

The disadvantages associated with plasma spraying include:

- Air plasma spraying equipment tends to require more investment than arc and flame spraying. Equipment used for vacuum plasma, or low-pressure plasma, and controlled atmosphere plasma spraying has a very high capital cost. These are probably the most expensive thermal spraying processes.

- It is a line-of-sight process, similar to all other thermal spraying processes, making it difficult to coat internal bores of small diameters or restricted access surfaces.

- The plasma spray gun usually experiences rapid deterioration of the inner gun electrodes and other internal components. This leads to frequent replacement of gun electrodes, and the need for quality control to maintain coating consistency.

- The high temperatures associated with the plasma jet can result in carbide decomposition or excessive oxidation when spraying in air, giving carbide coatings with lower hardness or metallic coatings with higher oxide levels compared with HVOF sprayed coatings.

- The equipment is not suitable for manual operation and requires use of automated gun manipulators.

Source:

TWI