HARD-SURFACING

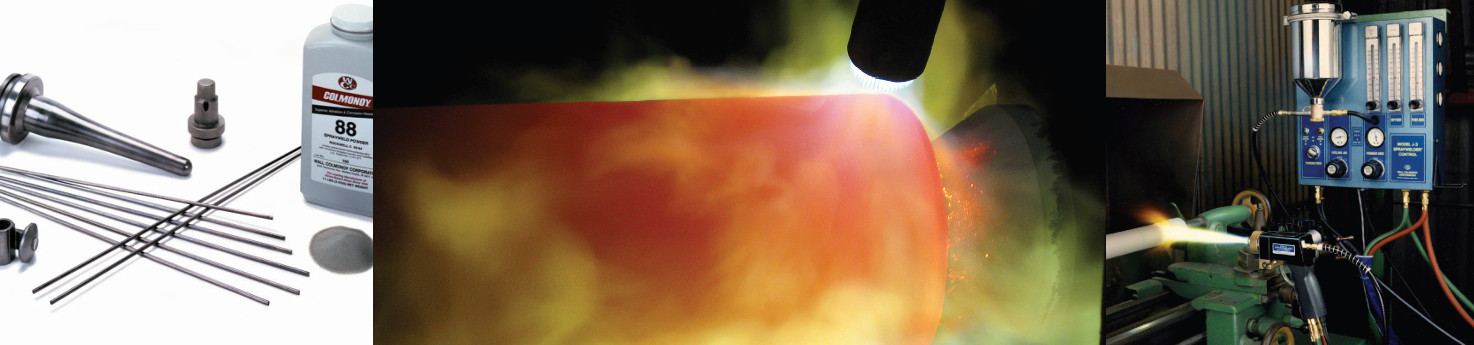

Hard-surfacing involves the use of a hard-surfacing alloy (in

powder, rod, wire or castings form) to provide an excellent defense

against wear mechanisms such as abrasion, erosion, corrosion and

high-temperatures encountered in service to your new or old

equipment.

The key benefits of hard-surfacing are as follows:

HARD-SURFACING ALLOYS

HARD-SURFACING EQUIPMENT

Contact us

for technical data sheets, more information or any other enquiries.

The key benefits of hard-surfacing are as follows:

- Minimizes downtime to replace worn or broken components (hard-surfaced parts can last up to 3 times longer than non-surfaced ones).

- Reduces spare parts inventory by reducing the amount of replacements needed.

- Reduces costs. On older equipment, in particular, hard surfacing costs 25 to 75 percent less than replacing worn parts.

HARD-SURFACING ALLOYS

| ALLOY | BRIEF | FORMS |

| COLMONOY® Nickel-based Alloys |

The Colmonoy family of nickel powder and nickel rods offer superior wear protection, retaining their hardness up to 600°C (1112°F) with significant resistance to oxidation. | To suit different application methods, our Surfacing Alloys are available in a full range of sizes and specifications as Powder, Rod, Wire, and Castings. Powders can be Gas or Water atomized and produced to specific alloy formulations. |

| WALLEX™ Cobalt-based Alloys |

These cobalt alloys have excellent wear and corrosion resistance and can withstand elevated temperatures. | |

| Customer-specific Alloys | Many customers have applications which require specific alloys in order to achieve specific required coating properties. We can work with you to help address specific requirements. |

HARD-SURFACING EQUIPMENT

| EQUIPMENT | BRIEF |

| Spraywelder™ System | The reliable Spraywelder™ System offers tight spray patterns and high spray rates to produce dense, wear resistant overlays. |

| Fusewelder Torch® | The Fusewelder Torch® is a special oxyacetylene torch which preheats the base metal, sprays powdered alloy and fuses deposits to the workpiece – all with one integrated unit. |